On-Site Diesel Fuel Polishing Services in Ontario and Quebec

Services We Provide

- On -site fuel analysis including ISO particulate and water content measurements

- Consultation of fuel related issues

- Fuel polishing for tanks between 10 liters and 2,000,000 liters

- Installation of fully automated AXI Fuel Polishing Systems

- All Perfect Fuel Preservation Limited personnel are fully licensed TSSA PM 2/3

The continual trend towards ultra low emissions has meant significant changes in the manufacture of diesel fuel. The removal of sulfur to below 15 parts per million and the advent of biodiesel into the mainstream delivery of diesel fuel mean that fuel must now be maintained on a regular basis. This maintenance goes beyond simply adding biocides and now must include very specific forms of fuel polishing by licensed professionals. Maintaining fuel to specific ISO standards is mandatory and in most cases critical to the warranty of the engine, low emissions and maximum engine performance.

This AXI STS 6000-30 is one of 4 units that maintains fuel at a major Canadian bank data centre. Each tank contains 140,000 liters of fuel. This system is quiet, trouble free and only requires a filter change annually.

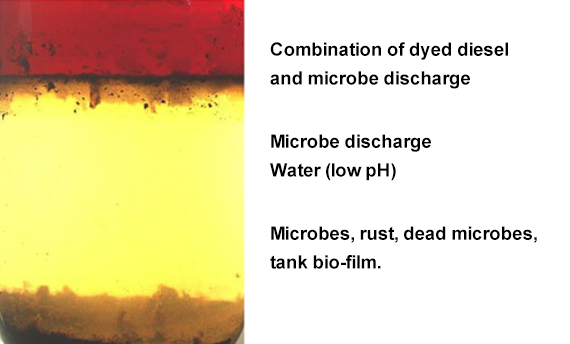

This fuel pictured above is actually salvagable and can be returned to fully useable fuel. It does require some expertise to seperate all the various layers and be left only with the red fuel shown at the top of the sample. This sample caused major damage to the tank because of rust and the water shown at the bottom of the sample is very acidic. Unfortunately the tank could not be saved but we did save the fuel and was pumped into the new tank in excellent condition.

Services We Provide

- On -site fuel analysis including ISO particulate and water content measurements

- Consultation of fuel related issues

- Fuel polishing for tanks between 10 liters and 2,000,000 liters

- Installation of fully automated AXI Fuel Polishing Systems

- All Perfect Fuel Preservation Limited personnel are fully licensed TSSA PM 2/3

The continual trend towards ultra low emissions has meant significant changes in the manufacture of diesel fuel. The removal of sulfur to below 15 parts per million and the advent of biodiesel into the mainstream delivery of diesel fuel mean that fuel must now be maintained on a regular basis. This maintenance goes beyond simply adding biocides and now must include very specific forms of fuel polishing by licensed professionals. Maintaining fuel to specific ISO standards is mandatory and in most cases critical to the warranty of the engine, low emissions and maximum engine performance.

This AXI STS 6000-30 is one of 4 units that maintains fuel at a major Canadian bank data centre. Each tank contains 140,000 liters of fuel. This system is quiet, trouble free and only requires a filter change annually.

This fuel pictured above is actually salvagable and can be returned to fully useable fuel. It does require some expertise to seperate all the various layers and be left only with the red fuel shown at the top of the sample. This sample caused major damage to the tank because of rust and the water shown at the bottom of the sample is very acidic. Unfortunately the tank could not be saved but we did save the fuel and was pumped into the new tank in excellent condition.